Basic introduction to PLC

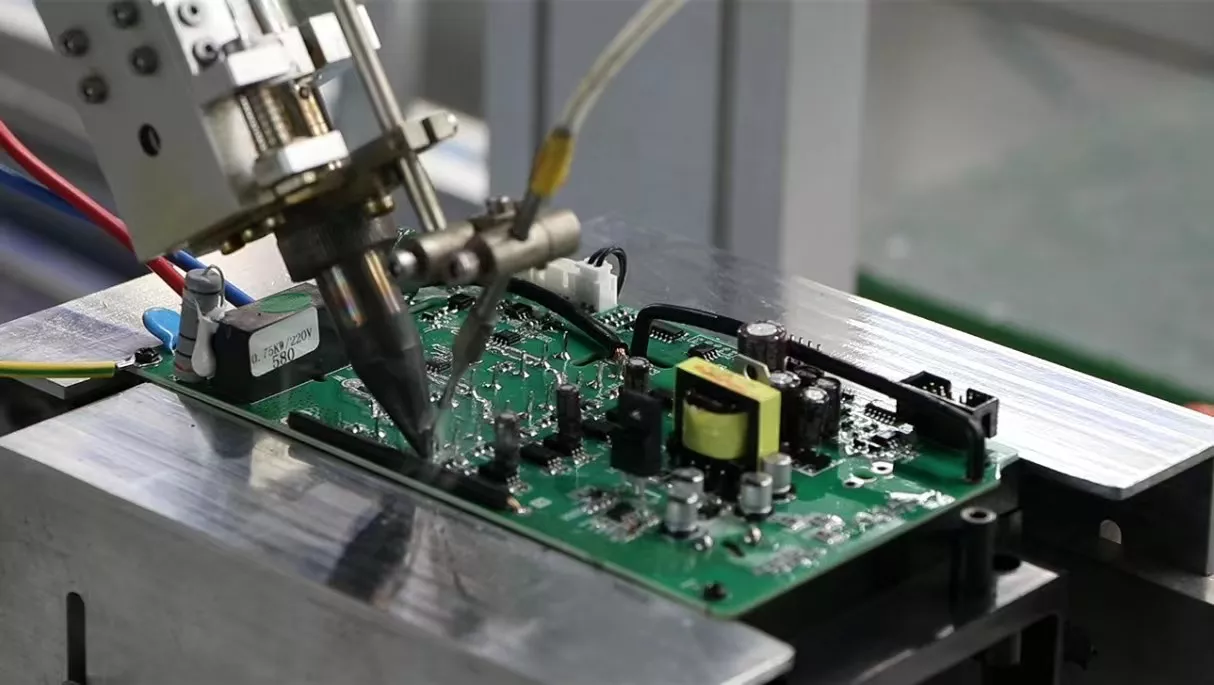

A Programmable Logic Controller (PLC) is a computer designed to operate reliably under harsh industrial environments such as extreme temperatures, wet, dry, and/or dusty conditions. PLCs are used to automate industrial processes such as a manufacturing plant’s assembly line, an ore processing plant, or a wastewater treatment plant.

They were initially designed to replace electromechanical relay systems in order to offer a simpler solution for modifying the operation of a control system. Rather than having to rewire a large bank of relays, a quick download can change the operation of a PLC.

Components of PLC

The hardware components of a PLC include the following: Processor, Power Supply, Programming Device, and Input, Output Modules.

I/O modules are connected to digital or analog field devices.

- Examples of digital output signals include Lamp, Coil, Buzzer, Relay, Motor, Fan, Heater, Actuator, Solenoid Valve and more.

- Analog I/O modules are usually given voltage or current in the form of an analog signal.

Types of PLC

There are two common types of PLC: integral type, such as Siemens and ABB, and expandable type, such as GCAN.

The integral PLC is suitable for standardized projects, while the scalable PLC is suitable for projects of different specifications and the preliminary test and evaluation work of the project.

Looking for a Expandable PLC for your next project ? Click to learn more!