The reasons for CAN bus failure are different. Here are some common reasons and their corresponding solutions:

1. Physical layer failure

Cable damage

Reason: The cable may be damaged due to wear, aging or external environmental factors (such as corrosion, water ingress, etc.), resulting in interruption or complete interruption of signal transmission.

Solution: Check the defects of the cable. If damaged, replace it with a new cable. Ensure that the waterproof, moisture-proof and corrosion-proof measures of the cable are in place.

Connector failure

Reason: The connector may cause interruption or interruption of signal transmission due to poor contact, corrosion or damage.

Solution: Check the contact of the connector. If the contact is poor or corroded, clean or replace the connector. Ensure that the connector is reliably connected.

Poor grounding

Reason: Poor grounding may cause electromagnetic interference and affect the quality of signal transmission.

Solution: Check the grounding point to ensure good grounding. Increase the number of grounding points and the reliability of grounding resistance.

2. Data warehouse layer failure

Different communication baud rates

Reason: Different nodes may use different communication baud rates, resulting in failure to communicate.

Solution: Make sure all nodes use the same communication baud rate. When configuring the node, check the baud rate setting carefully.

Protocol error

Reason: The data sent by the node may not comply with the CAN protocol specification, causing the data packet to be discarded or misinterpreted.

Solution: Check the protocol implementation of the node to ensure that it complies with the CAN protocol specification. Debug or update the software for nodes that do not comply with the specification.

Frame error

Reason: The packet data may be disturbed or damaged during transmission, resulting in frame errors.

Solution: Check the error detection and handling mechanism of the data queue layer to ensure that it can correctly handle frame errors. Add error detection and correction mechanisms to improve the reliability of data transmission.

3. Network topology failure

Terminal resistance is not matched

Reason: The CAN line CANH and CANL pins inside the CAN transceiver chip will have an open-drain structure. If there is no matching resistor or abnormal matching resistor between CANH and CANL, communication problems will occur.

Solution: Match the appropriate terminal resistor, which is usually installed at the farthest end (farthest distance) of the physical body, and the conditional matching resistor appears in pairs, with one resistor matching at the head and tail ends.

Overcoming excessive capacitance

Cause: Excessive rising capacitance will affect the rising speed of the CAN waveform and cause communication abnormalities.

Solution: Check whether there are external capacitors on the CAN bus, whether there are parasitic capacitances of protective devices (such as TVS, etc.) that are too large, and appropriately reduce the capacitance. Or reduce the working baud rate to extend the bit time and reduce the impact of capacitance, but (if the capacitance is too large, it may not be effective).

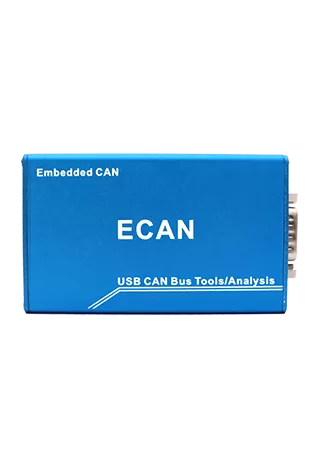

Click here to learn more: CAN Bus Analyzer Series | GCAN PLC & Coupler

Duplicate device address settings

Cause: When there are multiple devices on an entry, if the device address settings are repeated, communication conflicts will occur.

Solution: Check and repeat the device address to ensure that each modified device has a unique address.

Network load is too high

Cause: Too many nodes or too large data packets may cause the network load to be too high, affecting the real-time and reliability of data transmission.

Solution: Reasonably allocate the number of nodes to avoid network overload. At the same time, the network load can be optimized by increasing the network bandwidth, reducing the data packet size, or adjusting the data transmission frequency.

IV. Software failure

Program error

Cause: Programming logic errors, memory overflow, or improper exception handling may cause the node to fail to work normally or crash.

Solution: Check the program code and fix the error. Debug and test the node software to ensure its stability and reliability.

Resource conflict

Reason: Multiple nodes accessing shared resources at the same time may cause data interruption or system crash.

Solution: Optimize resource access strategy to avoid resource conflict. For example, use time-sharing multiplexing, priority scheduling and other methods to manage resource access.

V. Electromagnetic interference

External electromagnetic field interference

Reason: External electromagnetic fields may hinder the signal transmission of CAN interrupts, resulting in unstable or erroneous communication.

Solution: Add external mitigation measures to reduce the impact of electromagnetic fields. For example, use mitigation cables, mitigation connectors, etc. to reduce the impact of electromagnetic fields.

Power supply

Reason: Power supply rotation may cause the device to fail to work or be damaged.

Solution: Use a stabilized power supply to reduce the impact of power supply fluctuations on the device. At the same time, add power supply auxiliary measures to improve the stability and reliability of the power supply.

If you need a USBCAN analyzer for CAN communication intrusion detection, please feel free to contact us at info@gcanbus.com/13644001762