Varias interfaces de PLC (controlador lógico programable) desempeñan un papel vital en los sistemas de control de automatización industrial. Estas interfaces no sólo realizan el intercambio de datos y la comunicación entre el PLC y los dispositivos externos, sino que también garantizan la estabilidad y fiabilidad de todo el sistema de control. Las siguientes son las funciones principales de varias interfaces de PLC:

1. Interfaz de entrada

La interfaz de entrada es un puente que conecta el PLC con fuentes de señales externas (como sensores, botones, interruptores, etc.). Su función es convertir las señales externas en señales digitales que puedan ser reconocidas por el PLC. De acuerdo con los diferentes tipos de señales, la interfaz de entrada se puede dividir en interfaz de entrada digital e interfaz de entrada analógica.

Interfaz de entrada digital: se utiliza para recibir señales de conmutación, como la pulsación y liberación de un botón, el estado de encendido y apagado de un sensor, etc. Estas señales se expresan en forma binaria (0 ó 1), representando lógicamente "encendido" o "apagado". La interfaz de entrada digital garantiza la estabilidad y la antiinterferencia de la señal de entrada a través de medios técnicos como el aislamiento fotoeléctrico.

Interfaz de entrada analógica: se utiliza para recibir señales analógicas que cambian continuamente, como las señales de salida de sensores como temperatura, presión, caudal, etc. Estas señales suelen ser de tensión o corriente, y su tamaño cambia continuamente dentro de un rango determinado. La interfaz de entrada analógica convierte las señales analógicas en señales digitales a través de un convertidor A/D para su procesamiento por el PLC.

2. Interfaz de salida

La interfaz de salida es el canal a través del cual el PLC envía señales de control a actuadores externos (como motores, electroválvulas, indicadores luminosos, etc.). Dependiendo del tipo de señal, la interfaz de salida también puede dividirse en una interfaz de salida digital y una interfaz de salida analógica.

Interfaz de salida digital: se utiliza para emitir señales de conmutación para controlar el estado de encendido/apagado de dispositivos externos. La interfaz de salida digital envía las señales de control correspondientes a dispositivos externos basándose en los resultados de la operación lógica interna del PLC. Los tipos de interfaces de salida incluyen el tipo de relé, el tipo de transistor y el tipo de tiristor, cada uno de los cuales tiene sus escenarios de aplicación específicos y sus ventajas y desventajas.

Interfaz de salida analógica: se utiliza para emitir señales analógicas que cambian continuamente, como señales de tensión o corriente. Estas señales se utilizan para controlar dispositivos que requieren un ajuste continuo, como la velocidad del motor, la apertura de válvulas, etc. La interfaz de salida analógica convierte las señales digitales del interior del PLC en señales analógicas mediante un convertidor D/A, y las envía a dispositivos externos a través de circuitos de accionamiento adecuados.

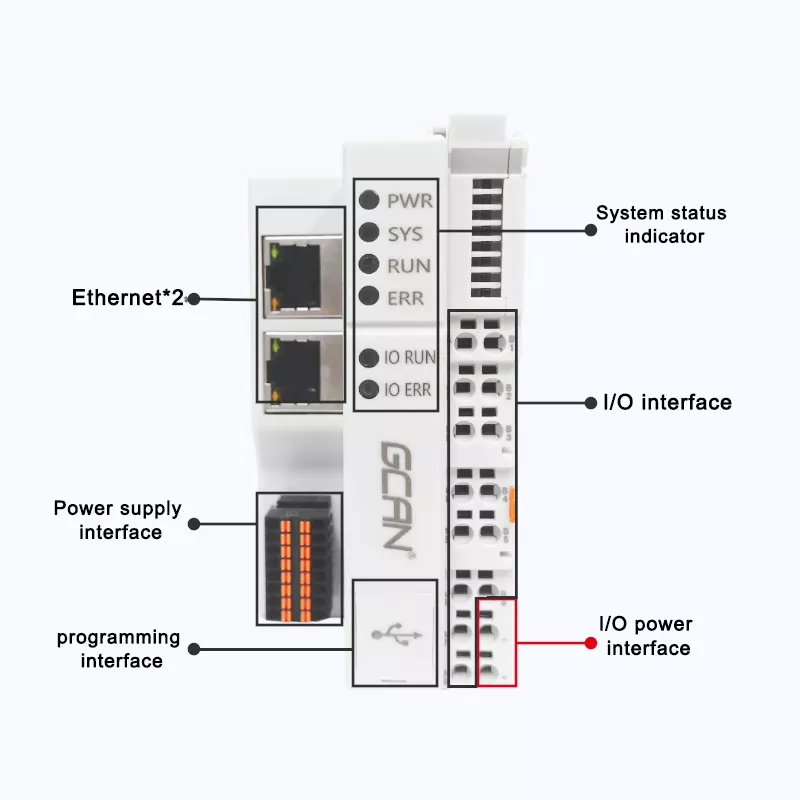

3. Interfaz de comunicación

La interfaz de comunicación es el canal por el que el PLC se comunica con otros dispositivos (como ordenadores, interfaces hombre-máquina HMI, otros PLC, etc.). Las interfaces de comunicación comunes incluyen RS-232, RS-485, Profibus, Modbus e interfaces Ethernet.

Interfaz RS-232: se utiliza principalmente para la comunicación a corta distancia y baja velocidad entre dispositivos, como la depuración y la transmisión de datos entre el PLC y el ordenador.

Interfaz RS-485: adecuada para comunicaciones de larga distancia y alta velocidad entre dispositivos, a menudo utilizada para conectar PLC con estaciones remotas de E/S, instrumentos inteligentes y otros dispositivos.

Interfaz Profibus: protocolo de comunicación utilizado en el campo de la automatización industrial, compatible con la comunicación de alta velocidad y múltiples tipos de datos, ampliamente utilizado en la comunicación entre PLC y dispositivos inteligentes de E/S.

Interfaz Modbus: protocolo de comunicación serie que admite la comunicación entre varios dispositivos maestros y esclavos, utilizado a menudo para conectar PLC con instrumentos inteligentes, colectores de datos y otros dispositivos.

Interfaz Ethernet: uno de los protocolos de comunicación LAN más populares en la actualidad. Se utiliza ampliamente en la comunicación entre PLC y ordenadores, HMI y otros dispositivos debido a su alta velocidad de transmisión de datos, buena compatibilidad y muchos dispositivos conectables.

4. Interfaz de funciones especiales

Además de las interfaces comunes mencionadas anteriormente, el PLC también puede estar equipado con algunas interfaces de funciones especiales, tales como ranura para tarjetas SD, interfaz USB, etc. Estas interfaces se utilizan para satisfacer los requisitos específicos de la aplicación, tales como el almacenamiento de datos, copias de seguridad, actualización de programas, etc.

Somos un fabricante profesional de controlador lógico programable PLC en China con más de 10 años de experiencia en el suministro de exportación. Si usted lo necesita, por favor no dude en contactar con nosotros 008613644001762/info@gcanbus.com