PLC 테스트 및 제어는 PLC 시스템의 기능, 성능 및 안정성을 검증하기 위해 설계된 다각적인 프로세스입니다. 다음은 PLC 테스트 및 제어의 주요 단계와 방법에 대해 간략하게 설명합니다.

1. PLC의 전원 공급 및 입력/출력 상태를 확인합니다:

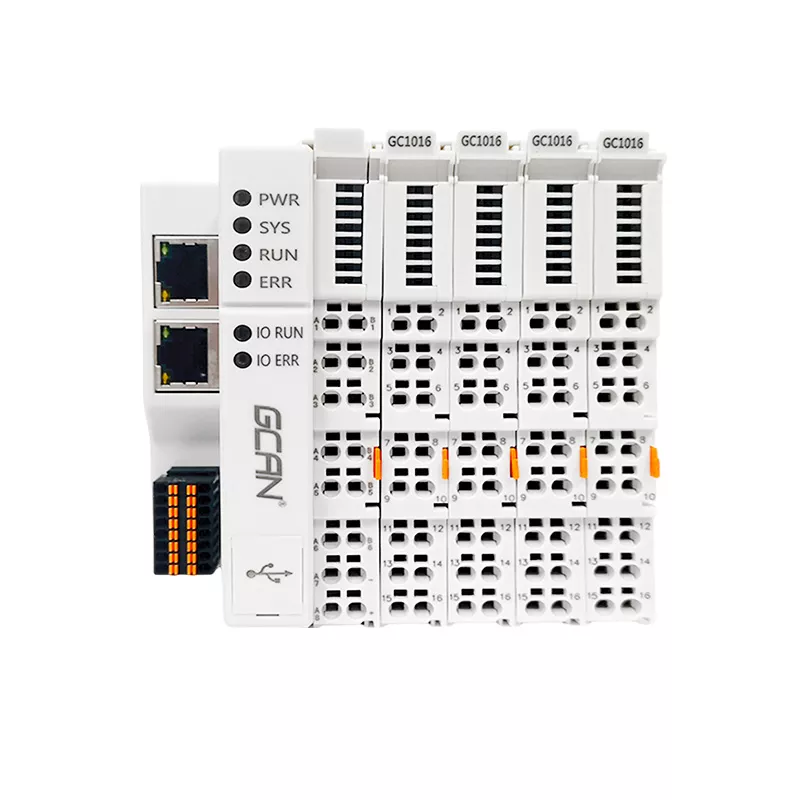

(1) PLC의 전원 표시등, 오류 표시등, 입력/출력 표시등의 상태를 관찰하여 전원 공급 문제 또는 입력/출력 이상 여부를 확인합니다.

(2) 작동 버튼, 비상 정지 버튼, 작동 표시기, 실린더 및 리미트 스위치 등을 포함한 IO 포인트를 테스트하여 PLC와 외부 장치 간의 연결 및 통신이 정상인지 확인합니다.

2. 소프트웨어 진단 기능을 사용합니다:

(1) 많은 PLC에는 하드웨어 오류를 감지하고 오류 정보를 출력할 수 있는 진단 프로그램이 내장되어 있습니다. PLC의 프로그래밍 소프트웨어에 액세스하거나 특정 진단 도구를 사용하여 진단 정보를 읽고 분석하여 장애의 특정 원인을 파악할 수 있습니다.

(2) 실제 값이 예상 값과 일치하는지 비교하여 결함 지점이 있는지 확인합니다.

PLC 프로그래머블 로직 컨트롤러 중국 제조업체 저렴한 가격

3. 로직 프로그램을 확인합니다:

(1) 다음을 주의 깊게 확인합니다. PLC 로직 프로그램에서 로직 조건, 타이머, 카운터 등이 올바르게 설정되고 실제 장비 작동과 일치하는지 확인합니다.

(2) 로직 프로그램에서 오류 감지 및 경보 로직을 확인하여 잠재적 오류 지점이 있는지 확인합니다.

4. 통신 상태 확인:

(1) PLC가 휴먼 머신 인터페이스(HMI), 센서 또는 액추에이터와 같은 다른 장치와 통신하는 경우 통신 링크 및 통신 프로토콜의 설정을 확인하십시오.

(2) 고장 진단을 위해 PLC의 네트워크 통신 기능을 사용하고, 네트워크 분석 도구를 사용하여 통신 프로세스를 모니터링하고, 데이터 패킷 전송이 정상인지 확인합니다.

5. 하드웨어 테스트:

(1) 로직 분석기, 오실로스코프 및 기타 하드웨어 테스트 장비와 같은 결함 감지를 위한 전문 진단 도구를 사용합니다.

(2) 대형 시스템의 경우 테스트 테이블을 설정하고 테스트 후 표시해야 합니다. 시공 과정에서 배선 오류가 발견되면 즉시 처리해야 합니다.

6. 기계적 구조와 모터 부하를 확인합니다:

(1) 기계 구조물 등이 고정되어 있는지, 모터 부하가 제대로 보호되어 있는지 확인하여 사고를 방지하세요.

7. 수동 모드/반자동 모드 및 관련 논리적 관계 디버깅:

(1) 생산 공정에 따라 자동 모드를 디버그하여 PLC가 다른 모드에서 정상적으로 작동할 수 있는지 확인합니다.

8. 로그 파일 및 알람 정보를 확인합니다:

(1) PLC 시스템은 일반적으로 로그 파일과 알람 정보를 기록하여 오류 이벤트를 기록하는 데 사용할 수 있습니다. 이러한 파일을 확인하여 장애가 발생한 시기, 유형 및 위치를 확인할 수 있습니다.

9. 하드웨어 재설정:

(1) 경우에 따라 일시적인 문제를 해결하기 위해 하드웨어 재설정 방법을 사용할 수 있습니다.

코드시스 프로그래밍을 지원하는 PLC가 필요한 경우 다음 주소로 문의해 주세요. 86 136 4400 1762 를 클릭하세요.